Our Story

1993 | Nester Hosiery is Born

After 20 years of working in the sock manufacturing industry, Marty Nester decides he can add something to the process and founds Nester Hosiery. The family owned and operated business gets its start producing unfinished cotton crew socks on first-generation, belt-driven machinery.

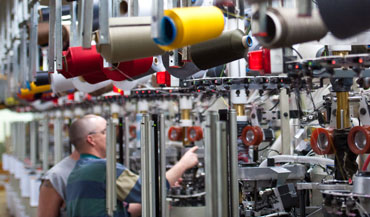

1995 | Investment in the company's first technical knitting machines

Nester Hosiery expands their capabilities of sock manufacturing with 54 needle Moreni and 84 needle Crawford knitting machines.

1995 | Working with Merino wool

Housed in an old grocery building in Dobson, NC, Nester Hosiery discovers the advantages of working with and wearing wool. The factory makes its first of many investments in modern knitting equipment, outfits the facility to become a top-to-bottom sock processor and starts manufacturing high performance socks for outdoor enthusiasts. Retailers notice, and Nester Hosiery begins to develop partnerships with premier outdoor brands.

1998 | Expanding Capabilities

By this time, Nester Hosiery is well on its way to becoming a world leader in wool sock innovation and production, incorporating performance synthetics into its products. The factory continually adds new machinery, allowing it to craft any type of sock – heavyweight / thermal, midweight / everyday, lightweight / multi-sport, ultra-lightweight, and beyond.

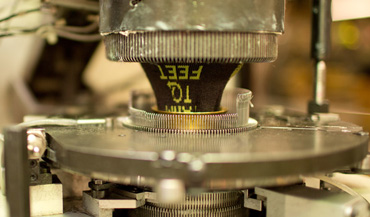

2001 | Seamless Knitting Arrives

Nester purchased its first machinery with seamless toe closure capabilities. This was the first of many and this type of knitting would become the majority of production within a few years.

2001 | Partners in information technology

Nester Hosiery begins its long-term partnership with software development company Mobile Foundry. This partnership enables Nester to build a custom Enterprise Resource Planning (ERP) system, SockInfo® that provides total visibility into supply, demand, and production operations. Order processing, shipping, inventory management, and sales forecasting tools and reports enable Nester to focus on making great socks.

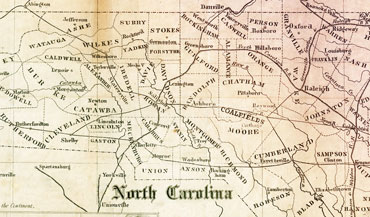

2002 | Relocation to Mount Airy, NC

Nester expands and streamlines its operations, setting up shop in a larger facility formerly owned and occupied by Brown Wooten Mills in Mount Airy.

2002 | Licenses Woolrich

The company finds a brand partner in, Woolrich, the original outdoor clothing company, established in 1830. Nester Hosiery begins developing its own full line of branded socks that are made seasonally and sold globally.

2004 | Purchase and refurbishment of the former Ballston Knitting facility in Mt. Airy, NC

Nester Hosiery purchases the Ballston Knitting plant, which is 250 percent larger than its former location and is conveniently located right up the street. The company begins converting the building into a high efficiency, 21st century manufacturing center and plans for a gradual move. The relocation is completed in 2005, allowing Nester to significantly increase volume to meet global demand and become more efficient than ever. This is Nester Hosiery's current home today.

2005 | Purchase of ACC Sales

Nester Hosiery acquires ACC Sales – a small company of sock specialists in Burlington, NC, with a wealth of experience in sock manufacturing – and in the process gains four skilled executives. With the acquisition of ACC Sales, Nester Hosiery continues to become a world leader in sock production.

2007 | Launch of inventory management system

Nester Hosiery builds and implements a customized warehouse inventory management system, which provides real-time inventory tracking throughout the plant. Every package, cone of yarn, and sock is located and tracked with hand-held scanners.

2008 | Expansion of leadership

A new framework of leadership is established for the long haul with talent and experience in every position.

2009 | Supply cycle visibility

Nester Hosiery houses one of the most experienced teams of designers, technicians and hosiery workers in the industry. Its employees are as high performance as its products. And its technology is always evolving; Nester’s in-depth tracking systems now connect every cone of yarn to every pair of socks, even tracing back to individual wool farms, for visibility of exactly which raw materials go into every batch of socks.

2009 | Conservation Alliance

Supporting outdoor recreation and land conservation, Nester Hosiery joins with the Conservation Alliance, a group of outdoor industry brands who partner with organizations to protect wild places for their habitat and recreational value.

2010 | Nester Hosiery begins to develop the Farm to Feet® brand of socks

Kelly Nester is inspired to create Nester's own brand of socks, Farm to Feet®, championing the story of the American worker and the American supply chain. Farm to Feet® takes the idea of supply cycle visibility to a whole new level, featuring a 100% American-made product: from the merino wool, to the processing, to the knitting, and even the packaging and displays, all materials and manufacturing is to originate from the United States.

2010 | Outdoor Industry Association

Nester Hosiery joins the OIA, an industry-wide collaborate group, to further our commitment to sustainability. Nester Hosiery begins working with the Sustainability Working Group, which is a collection of brands, retailers and manufacturers who focus on industry issues that affect the environment.

Nester Hosiery begins working with other OIA members to create the Eco Index, which evolved into what is now the Higg Index. The Higg Index is an industry tool used to self-assess sustainability efforts and allow brands, retailers and manufacturers to benchmark themselves against other businesses using the tool. Nester Hosiery was an early adopter of the Higg Index and has been using the tool to help set environmental goals for the past several years.

2013 | Nester Hosiery launches Farm to Feet® at the F13 ORWM

Made with 100% US ingredients, by US workers in US facilities, Farm to Feet® is officially launched at the Fall 2013 Outdoor Retailer Winter Market. The supply chain is wholly based within the US: merino wool is sourced from American Sheep Industry ranches in the western US, shipped to and processed on the East Coast, and knitted in Mount Airy at Nester Hosiery.

2013 | Factory process overhaul with significant upgrades to finishing equipment

Steam tumbling, laser guided steam boarding, and automated packaging equipment are installed to the facility, improving efficiency and enhancing the manufacturing process.

2014 | Introduction of tablets

The Nester Hosiery technology team integrates tablet-based applications to implement a real-time process for communicating knitting quality issues back to the factory floor.

2016 | bluesign® system partner

We joined the bluesign® system in 2016. The bluesign® system focuses on environmental health and safety in the workplace with a strong emphasis on removing harmful chemicals from the supply chain. We are currently working to source bluesign® approved textiles to manufacture some of our products with. This will ensure that we are doing the least harm to workers, the environment, and consumers.

| Current

Nester Hosiery is well positioned for the future, as the company has deep roots in its supply chain, from wool growers to yarn processing companies to software developers. It enjoys solid, mutually beneficial relationships with its customers, brands, and licensing partners.

As a U.S. Manufacturer, Nester Hosiery produces the most innovative socks on the market with both domestic and imported materials. It also works with a global network of other manufacturers to import finished goods. Nester Hosiery does everything with an eye on the community, both locally and globally.